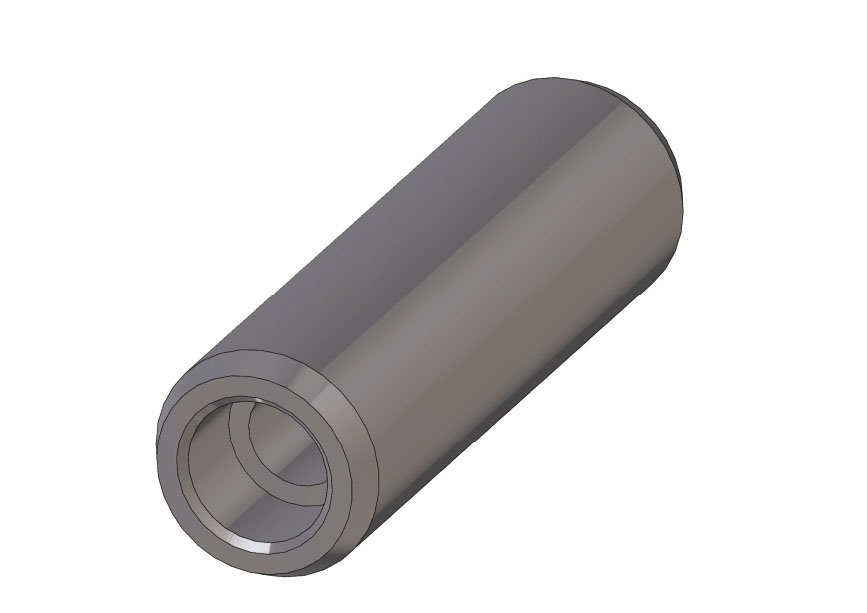

Thanks to a Mori Seiki CNC lathe with its bar-feeder and a second CNC lathe for finishing purposes, OMES can offer a wide range of steel pins based on customer’s design and technical require- ments. After heat treatments, all pins are ground on the outside diameter by a centerless CN grinding machine.

Recently, Widia pins have partially replaced the traditional hard- ened steel products as they proved on the field an average life- time up to 10 times higher in terms of abrasion and wear.

OMES purchases sintered blanks from leading national and international suppliers of tungsten carbide, then provides the machining on centerless, surface and cylindrical grinding machines in order to achieve final geometries and tolerances required by the customer.

OMES actual pins production is around 50.000 pcs/year for hardened steel and 10.000 pcs/year for Widia products.

Technical data

- OD: from 6 to 120 mm

- Length: up to 150 mm

- Materials:

• Steel: case-hardened (18ncd5), tempered steel (1.2842 – 1.3505), tool steel (1.2080 – 1.2379)

• Widia: ISO K01 – K05 – K10 - Hardness:

• Steels: from 60 to 64 HRC

• Widia: from 1.600 to 1.850 HV10 (87 – 93 HRA)