Omes also manufactures steel plates for the molding of the abrasive disks using its CN turning and grinding machines.

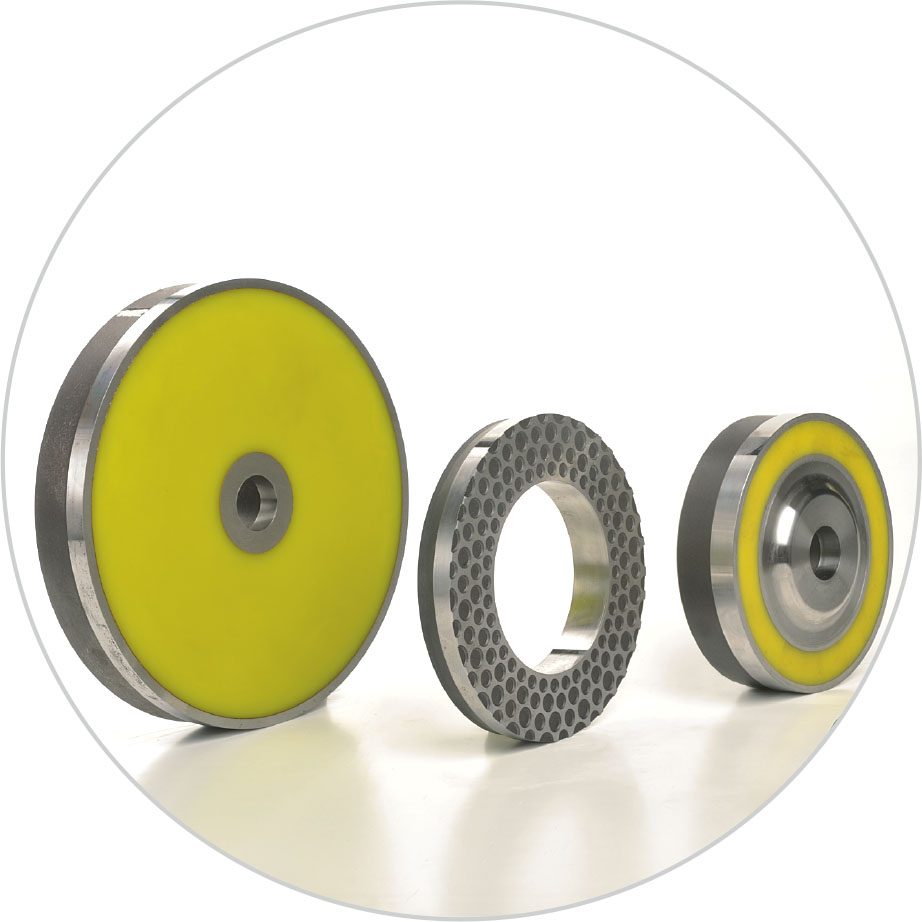

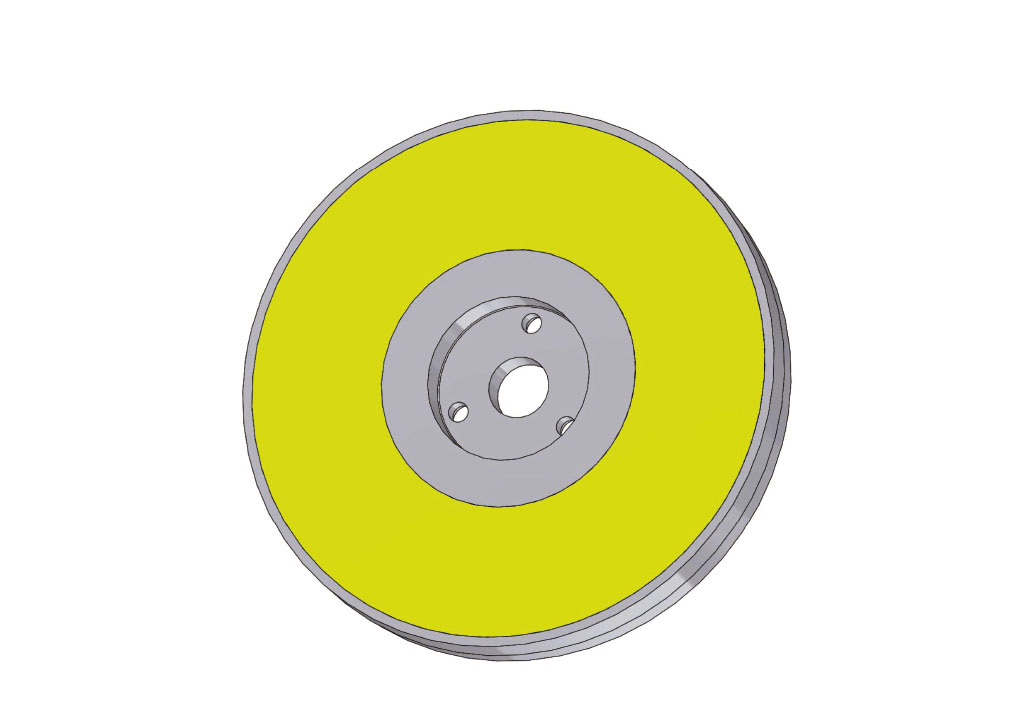

The process starts with the turning operation of the components in the mechanical shopfloor, then with the hardening treatment done outside, if requested, with the pouring of a layer of polyure- thane of 3 – 6 mm and as last operation with the grinding on CN cylindrical and surface grinding machines, to achieve internal, external diameters and heights requested by the technical drawings.

OMES actual molds and spare parts production is around 8.000 pcs/year.

Technical data

- ID: from 6 to 50 mm / OD: from 32 to 600 mm

- Height: up to 100 mm

- Materials:

• Case-hardened steel (18ncd5), tempered steel (1.2842 – 1.3505), tool steels (1.2080 – 1.2379) - Hardness:

• Steels: from 60 to 64 HRC

• Polyurethane: 90 – 95 Shore A; 60 – 70 Shore D